A focus on laser welding when Permanova hosted Laser Day

Home » A focus on laser welding when Permanova hosted Laser Day

The second Laser Day of the year took place on 17 October. It was hosted in Mölndal by Permanova Lasersystem AB, which organised the event in collaboration with Lasergruppen. The speakers included representatives from a variety of companies and industries, who talked about how lasers – in particular laser welding – has helped to strengthen their products and businesses.

Laser Day generates greater awareness of the potential of laser technology

Laser Day is held twice a year by Lasergruppen, an association whose purpose is to promote the engineering industry’s use of laser technology and to serve as a platform for its members to share their expertise and experience.

The aim of the Laser Days is primarily to bring the industry together, spread awareness of how companies are using laser technology, understand the possibilities that are in demand, and discuss current research. These days are an excellent opportunity for networking and sharing experiences. “We want to be a driver of laser technology in the Scandinavian industry and, as a supplier, this is an excellent opportunity to hear about developments in the industry and among our customers,” says Mikael Olsson, Laser Product Manager at Trumpf’s Swedish subsidiary in Alingsås and member of the board of Lasergruppen.

Permanova builds and supplies turnkey laser systems

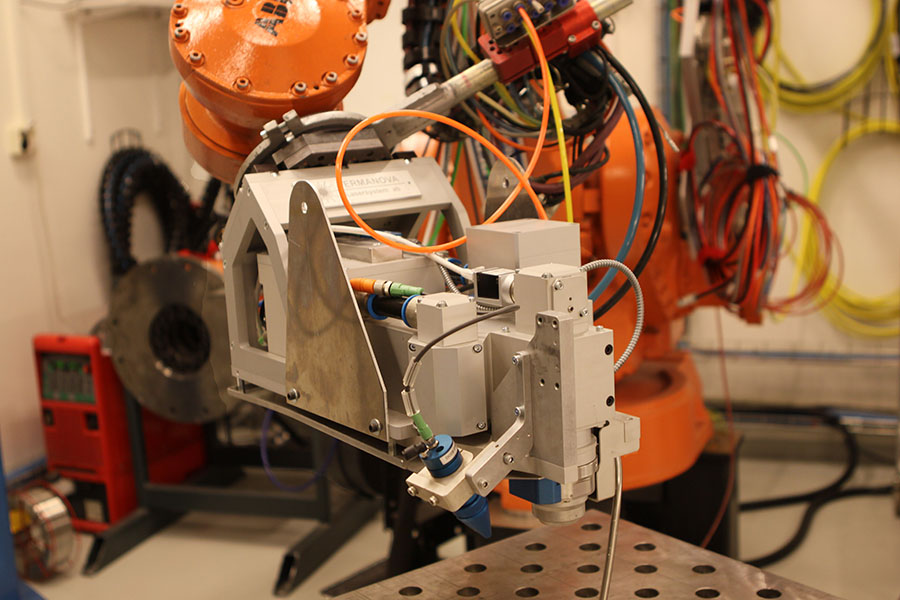

Once the chair of Lasergruppen, Johnny K. Larsson, introduced the association and its work, Håkan Grubb, CEO of Permanova Lasersystem AB and co-host for the day, explained more about the company. Permanova is an integrator, which means that it integrates components and produces turnkey laser systems. The systems are designed, developed, built, and installed for a customer of Permanova, which has been supplying industrial laser systems for almost 35 years.

The company works only with metalworking, and primarily in the areas of welding, hardening, and additive manufacturing using lasers. Increased productivity is the most common reason why customers choose to work with laser processes, as these have a high level of precision and deliver high-quality results with few deformations. The fact that Permanova has proprietary laser optics means that the customer’s optics can be tailored to their needs, which is a huge advantage for the customer and very unusual among integrators, even internationally.

Laser welding and additive manufacturing offer major advantages for the aerospace industry

One of Permanova’s customers is GKN Aerospace AB in Trollhättan (formerly Volvo Aero). Hans Falk talked about how laser welding and additive manufacturing are helping to make aircraft components such as engines lighter and more fuel efficient. The accuracy of laser welding and its potential for optimisation mean there is no need for post-processing, while the risk of cracking, stresses, and deformation is much lower. The result is the cost-effective production of a more fuel-efficient engine.

GKN currently uses additive manufacturing in several contexts, from fans and turbine blades to nozzles for Ariane rockets. Additive manufacturing has many advantages compared with more traditional manufacturing. Components with complex designs can be produced much more quickly and easily, at a significantly lower cost in terms of both production and the transport of the manufacturing materials.

Laser welding generates new customers and strengthens relationships with existing customers

Laser welding can help a company gain new customers, something which Börje Andermård at Brogren Industries AB talked about based on his company’s own experiences. The company is a partner of major market players (among them GKN) and helps them to complete certain end products by way of various industrial processes, including welding.

Börje talked about how the company entered the laser welding industry and how this helped to put the company on the map and give it a competitive advantage. Above all, the company has been able to retain its existing customers and satisfy their growing needs, as well as gain new customers thanks to Brogren’s investment in laser welding.

Sensitive products can also be laser welded without adverse effects

Gothenburg-based Alelion Energy Systems AB builds lithium-ion batteries and energy storage systems. Fredrik Lüsch (COO and CTO) talked about the rapid developments in the field of electrification.

For Alelion, the cleanness of the laser welding process is crucial, as the battery cells and electronics must not be contaminated or overheated. Laser welding allows materials to be fused together without damaging the product. The method is also cost-effective.

Following the talk from Alelion, Permanova presented its latest product, the PermaScan scanner tool. During lunch, visitors were given the opportunity to visit Permanova’s lab, where project engineer Robert Karlsson demonstrated the PermaScan in action.

The automotive industry is demanding cost-effective and simple solutions

Per Lindahl from Volvo Cars talked about how they work and have worked with lasers, and how this work could be developed in the future. Structures and the joining of materials often present challenges, and the company uses various laser processes in different parts of its production to achieve the best possible results. These processes include the laser welding of car roofs and doors (the latter using remote laser welding) and the laser soldering of tailgates.

Volvo emphasised that these methods are very important for the future of car manufacturing at the company, in terms of both form and function. Per emphasised in particular the importance of cost-effective and simple solutions in order to avoid overly advanced systems that require highly trained staff and pose a risk of becoming a sensitive part of the manufacturing process.

Laser welding and laser cutting deliver better product quality and generate new business opportunities

Björn Sjölin and Patrik Strandberg from SteelTech AB talked about how manufacturing can be developed by way of laser welding and laser cutting. Having previously welded primarily using TIG and not always being satisfied with the results, the company decided to also use start using laser welding to make its products. Its precision and minimal heat impact resulted in products with fewer deformations and little or no need for post-processing. In addition, the welding time itself was reduced to a fraction of what it had been.

The company, which mainly produces stainless steel products for caterers and the food industry, recently entered a completely new environment, quite literally. The reconstruction of the E45 motorway through central Gothenburg will result in around 700 metres of the road being lowered. The concrete supporting wall adjacent to this stretch will be covered with acid-resistant stainless steel. Both the steel and its elegant laser-cut motif of Gothenburg’s road network as seen from above have been developed by SteelTech. The motif will be illuminated at night, and the entire contract will be completed in May 2021.

The benefits of laser hardening and consideration of laser trends

Laser Day ended with Permanova’s Erik Vännman and Björn Lekander talking about selective hardening using lasers and some of the current trends in the industry. Erik explained, among other things, the many benefits of laser hardening, including a quick and automated process, the ability to build compact and flexible systems with short changeover times, high quality, and minimal post-processing needs.

Björn talked about the development of laser sources in the US and China, where manufacturers of smaller laser sources are a growing trend. Other topics touched upon included the potential for lasers in Industry 4.0, where measurements from optical sensors help to ensure more predictable production, as well as wage trends in China. The demands of newly graduated Chinese engineers for ever higher wages combined with an increasingly high degree of automation in European industry indicate that it will probably become increasingly profitable in the future to invest in laser expertise in Poland or Ukraine and to continue to invest in Sweden.

Laser Day at Permanova was a very successful and educational day with broad and enthusiastic participation by visitors from all over Sweden. During lunch, visitors were also given the opportunity to visit Permanova’s lab. Sven Olov Roos, a board member and one of Permanova’s founders, has long had a passion for customer events such as Laser Day. “Customer exchanges like these are very rewarding. It’s invaluable when we as an industry come together to discuss our experiences and our problems and solutions. Days like today show the full spectrum and breadth of the industry, and the huge benefit of this technology in a variety of applications.”

Anna Wallner | 2019-11-15