Our specialist areas for efficient production using lasers

Permanova Lasersystem develops, manufactures, and installs robotic laser systems for metalworking in the engineering industry with a view to improving the customer’s productivity, product quality, and profitability.

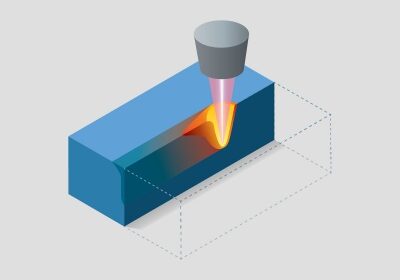

Welding

Laser welding uses a spot diameter of 0.5mm to ensure the absolute minimum heating of materials. The typical welding speeds for materials of up to a few millimetres in thickness is 6m/min.

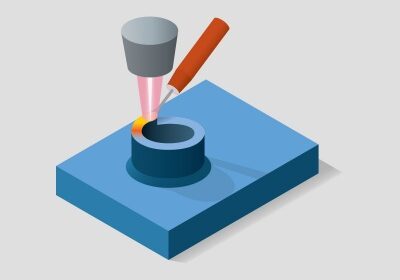

Additive manufacturing (AM)

Additive manufacturing (AM) is an increasingly popular technology, and it is one that lasers are very well suited to. With the help of an additive in the form of a powder or wire, structures can be built without the need for cutting-based processing.

We supply solutions to the following industries

Automotive industry – a pioneer of laser technology

Over the years, the automotive industry has introduced laser technology for several different reasons, including single-sided access, stronger and safer structures, design, and variant management.

Aerospace - always uses the latest technology

Welding using lasers results in reduced weight, better fuel economy, and a smaller environmental impact.

General industry

There are many reasons why companies are switching to laser technology. We’d like to discover yours!