Laser School: Part 8 – Implementation of an industrial laser station

Home »

In the eighth and final section of the laser school, we’ll look at how to implement a laser station in the engineering industry. We’ll go through the different implementation stages, explain the importance of calculations before asking for a quote, and look at the key things to consider when establishing a long-term, reliable, and profitable industrial laser process.

Level of automation and product design affect the implementation of lasers

The length of time the implementation of an industrial laser process takes depends on the complexity of the station and the type of station purchased. Generally it takes between 24 and 30 weeks from order to delivery. What often distinguishes one implementation from another is the level of automation on the production line. Another aspect of implementation that can distinguish one laser process from another, and thus its implementation, is whether there is a specific design for the products to be manufactured that may require the adaptation of the optical tool.

Calculations determine whether an investment in a laser process is profitable

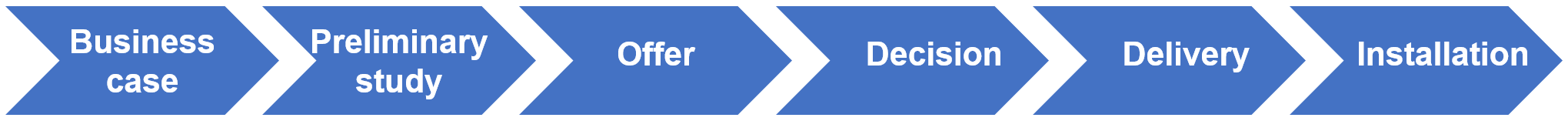

There are a number of steps to follow in the successful implementation of a laser process within the engineering industry.

The first step is to create a business case or calculation together with the laser supplier to determine whether an investment in a laser process will be profitable. The calculation is important as it helps to give an overall picture of the production and conditions. The calculation also helps the laser supplier to compile as accurate a quote as possible. The following information is required to produce a calculation:

- What are the current production/cycle times?

- How much additive is used and at what cost?

- How much time is spent on post-processing such as grinding and polishing?

- What is the volume of rejects?

Based on this information, the laser supplier estimates the impact on production if the current processing method were to be replaced by a laser processing method. The amount of time needed for the investment to pay for itself is also estimated.

The preliminary study indicates whether the product can be laser processed

Experienced laser supplier and dedicated client ensure good results

Following the preliminary study, a quote is provided that includes the design of the laser station. A decision, order, delivery, and installation of the laser station then follow. The delivery also includes training in how to use the equipment, as well as safety training. The installation process is usually similar, depending on the laser method, as the equipment often consists of a laser source, an optical tool, a robot, and laser housing. Before delivery, the laser supplier carries out a factory acceptance test (FAT) for the customer to approve the equipment. After delivery and installation, a site acceptance test (SAT) is carried out, where the parties go through the delivery together and approve it. Throughout the implementation process, it is important to work with an experienced laser supplier and to have a dedicated client in order to achieve good results.

Implementation of laser processing increases quality throughout production

Generally speaking, there are no long stoppages to production in connection with the installation of a laser station. The laser station is often set up alongside the current process in order to gradually transfer the products to the new laser process. The implementation of a laser station may also help to increase the quality of the entire manufacturing process. The products require good tolerances in order to be processed using lasers. Consequently, other equipment may need to be adapted to the laser process, which often raises the quality of the products and the production process.

Sustainable laser stations that can be adapted to different products

Permanova manufactures long-lasting laser stations, and it is not uncommon for them to still work well after more than twenty years of operation. Although the laser station still works, most products are usually developed and adapted in different ways over time, so we recommend purchasing a laser station that can be adjusted and adapted to different products. In addition, it is important to purchase the station from a supplier that is willing to make the adjustments needed for it to produce modern, sustainable, and high-quality products in the engineering industry.

This was the eighth and final part of laser school. We hope you have appreciated our laser school and acquired some new knowledge and inspiration in respect of how lasers can increase profitability in the engineering industry. If you have any questions, please don’t hesitate to contact me or one of my colleagues. All eight parts of laser school are available on our website under “Inspiration”.

skapa dev | 2020-01-16