Lasers in industry improve product quality and production efficiency

Home »

How can selective hardening using lasers make products last longer? And how can production in the engineering industry be sped up by replacing traditional processing and manufacturing methods with laser methods? In this article, we explain how different laser processes can improve the quality of your products and make your production processes more efficient.

Products that are reliable and durable and which have the correct tolerances

In the engineering industry, products are manufactured that must meet strict standards in order to live up to the end customer’s expectations. In order to deliver their full potential, the products not only must satisfy the requirements specifications, but they need to be reliable, durable, and of consistent quality. Consistent product quality can also help to ensure efficient production. When the products have the correct tolerances, they slot into all the manufacturing processes of the production line without creating interruptions or resulting in rejects.

How does laser welding contribute to high product quality?

How does laser welding contribute to efficient production?

Compared with many other welding alternatives, there are often fewer parameters to set in laser welding. Laser welding has only three parameters – power, speed, and focus. Many other welding parameters require the setting of parameters such as dimension, position, wire speed, and wire size. Fewer parameters means less maintenance, which results in shorter lead times and increased productivity.

How does laser cutting contribute to high product quality?

How does laser cutting contribute to high product quality?

Laser cutting ensures a finer cut than does gas or plasma cutting, resulting in good tolerances and surface aesthetics. The rougher tolerances of other methods risk the addition of extra production steps and can be difficult to correct. Laser cutting ensures good product quality, as the method has a limited heat effect on the material, which reduces the risk of deformation.

How does laser cutting contribute to efficient production?

Laser cutting is both quicker and more precise than gas cutting, for example. Laser cutting is usually an automated process that is cost-effective and easy to apply in a production line. All of the components of laser cutting equipment are mature products, making laser cutting a reliable and stable method. Thanks to automation, laser cutting equipment can be connected quickly, ensuring quick and readily available servicing.

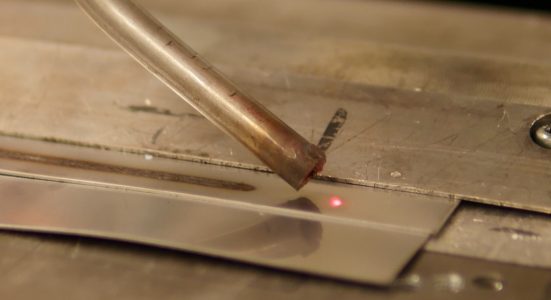

How does laser soldering contribute to high product quality?

How does laser soldering contribute to efficient production?

Since laser soldering results in a joint that requires no post-processing, a production step is removed as the joint does not need to be ground or covered with a compound before painting. Fewer production steps mean lower costs and quicker and more efficient production.

How does laser hardening contribute to high product quality?

How does laser hardening contribute to high product quality?

Laser hardening facilitates selective hardening, which reinforces very well-defined surfaces of the product. Using a concentrated laser beam, a small area is heated and then cooled by the surrounding material. By hardening only the areas that need it to the correct hardness, the desired material properties in the rest of the product can be left unchanged. Selective hardening also reduces the risk of the surrounding material cracking. An alternative to hardening is to fix consumable parts to the product, which may need to be replaced as they wear out.

How does laser hardening contribute to efficient production?

Laser hardening is a relatively quick process that is usually easy to integrate into the production line. Other hardening methods such as case hardening require furnaces, while induction hardening requires extra equipment. Laser hardening, however, can be done using industrial robots, for example.

How does additive manufacturing using lasers contribute to high product quality?

Products that have been made using additive manufacturing with lasers have material properties that are as good or better than those of products milled out of a cast material. With additive manufacturing you can build a structure from scratch, either as a standalone product or as part of another product. Additive manufacturing makes it possible to combine different material qualities so that the product meets specific requirements, such as for strength. The alternative is to have the same material quality for the entire product, despite the greatest stress being limited to a specific area of the product. Additive manufacturing also makes it possible to customise each component.

How does additive manufacturing using lasers contribute to efficient production?

Additive manufacturing is a flexible method which facilitates the easy adaptation of production for the manufacture of different product variants. The base material is purchased as a wire, which is compact and easy to store. It is a quick method with minimal post-processing requirements, which saves time, material, and money. Alternatives to additive manufacturing include casting and milling, but these are complex and expensive processes that require specialist tools and knowledge to achieve good results. Often, moulds are needed that take up a lot of space, and there is a limited number of suppliers who can deliver the right material quickly. Milling out the desired component is time-consuming and often results in a huge amount of waste material.

Permanova supplies modern and readily available laser equipment

Permanova supplies complete laser production systems tailored to your specific needs. We work in close contact with our customers and conduct tests in our lab together in order to find the perfect process for ensuring a high-quality product and a high level of efficiency in your production. For us, it is important that we are on hand for our customers even post installation to ensure high-quality production for years to come. Consequently we have a service organisation that is easy to get hold of wherever in the world you are. By supplying modern and readily available laser equipment, and by being on hand whatever the time or place, we hope to become your chosen laser partner!

If you have any questions about any of the laser processes described above, or if you want to find out more about Permanova and how we work, please contact me or visit our website for more information. And don’t forget to say hello on our social media channels!

Björn Lekander | 2019-12-11

How does laser cutting contribute to high product quality?

How does laser cutting contribute to high product quality? How does laser hardening contribute to high product quality?

How does laser hardening contribute to high product quality?